Welcome to

On Feet Nation

Members

-

Amanda Online

-

Allen Online

-

smithmorgan Online

-

Cassie M. Stephens Online

-

Adrian Online

-

Selma Online

Blog Posts

Top Content

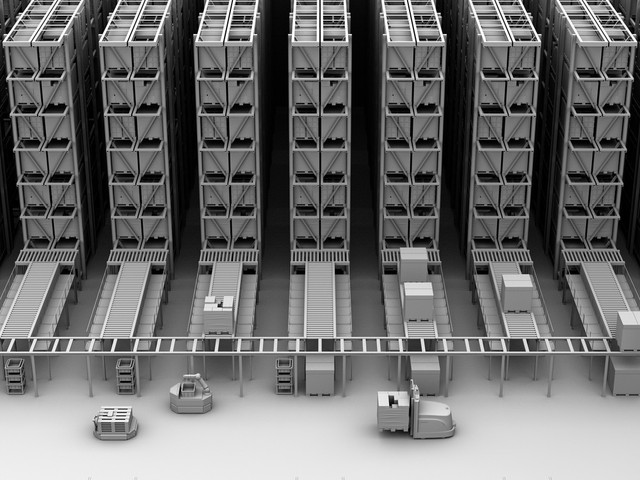

With robot unmanned forklifts, your storage becomes more flexible

A growing number of industries are turning to intelligent manufacturing to spur growth and innovation. As artificial intelligence and autonomous machines stacker forkliftgain traction, handling equipment like the AGV unmanned forklift is becoming more crucial in facilitating efficient production. Among the many industries that use this machine are e-commerce logistics, furniture and home appliances, electronics manufacturing, etc.

As a global industrial unmanned vehicle leader, we are committed to using technology to empower industrial vehicles and promote the application of flexible unmanned processes within node logistics. By applying core technologies such as 5G communication, artificial intelligence (AI), environment perception, deep learning, and servo control to the field of industrial unmanned vehicles, we create highly flexible industrial unmanned vehicles and logistics solutions that help enterprises quickly realize intelligent and scientific logistics management and improve logistics efficiency and economic benefits.

The "efficiency and safety" of Agv's unmanned forklift

The robot has always held a leading position in terms of technology, market share, and product quality. It is the core of the AGV unmanned forklift that puts efficiency first, safety first, and this is the primary consideration for various industries when purchasing an unmanned forklift.

For an AGV unmanned forklift to be considered efficient, it is not only about its running speed, but also its efficiency of execution at each link. The efficiency first means not only to realize the large-scale promotion of AVV unmanned forklift, but also to enhance the use value of the product to the greatest extent, and efficiency is exemplified by value, and safety, stability, and reliability are its foundations.

Unmanned forklifts by AGV can meet all the requirements of application enterprises, but safety is also an issue that cannot be ignored. Efficiency is the key to breaking the mold.

Increasing the efficiency and convenience of warehouse logistics with agv unmanned forklifts

It is important to plan a reasonable handling path

Intelligent warehouse logistics pre-planning route, under the satisfaction of the channel requirements and site requirements, to measure the shortest distance, reasonable planning layout, Robot agv unmanned forklift using SLAM laser navigation and sensing, multi-axis real-time motion planning and high-precision servo control technology can achieve Multi-vehicle scheduling, path planning, collision avoidance, task management and other functions.

Divide the volume weight of the material unit by two

It is important to analyze and observe the volume and weight of the goods, pallet type, etc., prior to assigning an AGV unmanned forklift. After fully considering all the details of the goods and the size of the goods placement site, it is important to properly equip the appropriate AGV unmanned forklift, which is conducive to rapid efficiency improvements and security protection.

Multi-vehicle cooperative handling

Several AGV unmanned forklifts can be used in different scenarios, including the MEF1-2000 pallet handling unmanned forklift, the MEC1-1400 indoor stacking unmanned forklift, and the MEF2-2000 outdoor handling forklift. In order to increase the efficiency, convenience, and speed of cargo handling, cooperative operations are beneficial.

Related article reading:

What are the reasons for the widespread use of unmanned forklifts i...

Unmanned intelligent forklifts are becoming increasingly popular fo...

Unmanned forklifts can be an important tool in warehouse management

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation