Welcome to

On Feet Nation

Members

-

Cassie M. Stephens Online

-

-

Blog Posts

Top Content

What’s the Purpose of Spot Drills?

Precision drilling and machining can seem more complex than it really is, with many specialized bits and processes making up the whole. While together they can be intimidating, typically they can be reduced down to relatively simple fundamentals.

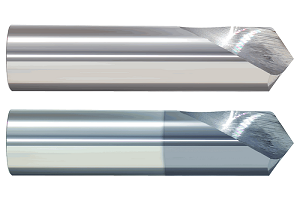

Spot drills are one example of this. Looking through a catalog of precision mills one will uncover a number of other specialized mills like chamfer mills, thread mills, variable end mills and spot drills. Each of them performs a highly prescriptive task, and spot drills are no exception.

So what is a spot drill used for? At the simplest level, spot drills are used to create a spot - hence the name - that serves as a guide for the mill that will be used to drill through a material.

Why create a spot? Well, depending on many factors, like the hardness of a material or slickness of the surface being drilled, a mill can walk or slip when being used. That would entirely counteract the purpose of precision drilling, which is to make a clear, extremely precise cut into a surface. Spotting a surface with a spot drill is a method taken as a precaution to prevent another bit from walking, traveling unduly over a surface or even from making a rough cut.

Not just any spot drill can be used, however. Due to the high speeds and great forces that are imparted to mills, a carbide bit must contact a surface at a very precise angle in order to prevent damaging itself or the material being worked. A spot drill should create a divot in the material being worked that is the same or a larger point angle than the drill that will subsequently be used. If the angle of the divot created is too sharp, it can damage or destroy the drill that next touches it.

A spot drill can also be used to create a chamfer in a surface. Sometimes a specialized chamfer mill is used for that purpose. A chamfer is a small recess worked into a surface so that joining materials such as screws will sit flush on the surface, which is a requirement in some applications. Keep in mind however that in order to create a chamfer with a spot drill, the spot drill must be slightly wider than the drill making the next hole.

To find the best spot drills and other carbide cutting tools that money can buy, take a trip to OnlineCarbide.com. Online Carbide offers carbide drills such as drill mills, thread mills, end mills, spot drill, chamfer mills and more at amazing prices. By selling directly to their customers instead of through a drawn out supply chain, they can keep prices down without sacrificing quality. In fact, all of Online Carbides mills and drills are produced right in the United States of America to extremely exacting standards. It’s like getting more for less, and that’s something anyone can get behind. Visit their site today to see their full line of carbide cutting tools.

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation