Welcome to

On Feet Nation

Members

-

Cassie M. Stephens Online

-

Leslie Online

-

Phillip Online

Blog Posts

Top Content

Spot Drills vs Center Drills

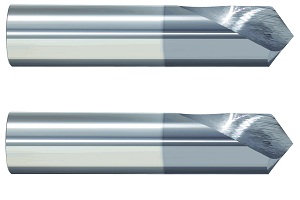

There are many different types of drill bits and drill like tools. Sometimes it can be a real challenge trying to tell them all apart. Two of the most commonly mixed up drills are spot drills and center drills. While these tools may look somewhat similar and seem to be interchangeable for certain applications, they have a few key differences that are important to note.

Spot Drills

Spot drills are short tools with a small pointed cutting surface. As their name suggests, these tools are primarily used to “spot” the location where a twist drill bit will be used. On hard surfaces like steel and other metals, drill bits have a tendency to deflect and “walk” off their mark. This can damage both your workpiece and your drill bit.

The point of a spot drill is to create a small dimple that a longer twist bit can easily fit into. This helps to ensure that your bit will find its mark without issue. The biggest consideration when choosing a spot drill is to ensure that the point angle of your spot drill is greater than the point angle of the longer twist bit being used. This will ensure that the bit contacts the bottom of the spotted divot instead of deflecting off its side.

Center Drills

Center drills are another short tool designed with a small point cutting surface. Unlike spot drills, center drills feature a central extension to their point. This small protrusion serves as a pilot drill while the rest of the cutting surface acts as a countersink to widen that pilot hole. These tools are designed to mark the center point of material so it can be prepared to be lathed.

Some machine operators will use a center drill in place of a spot drill. While these tools are certainly capable of creating a dimple in a workpiece, there are a few important differences in design that make them ill suited for spotting. Center drills typically have a more narrow point angle than spot drills, which makes them particularly ill suited for spotting. If you do spot with a center drill, you run the risk of your drill bit deflecting off of the edge of the divot created in your workpiece.

Both of these tools are important for machinists, but they are definitely not always interchangeable. Using the wrong milling cutter for a specific application can have devastating effects including damage to your workpiece or tools. If you are looking for high quality spot drills or center drills, you can find some amazing solid carbide options at Online Carbide. Their carbide tools are designed to offer the same performance as tools from other US manufacturers. You can visit their website at www.onlinecarbide.com to see a full list of their available drill bits and end mills. If you have any questions about the tools that they offer, you can reach out to a member of the Online Carbide team by sending an email to [email protected].

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation